On Site, Concrete Speaks Through the Abrams Cone

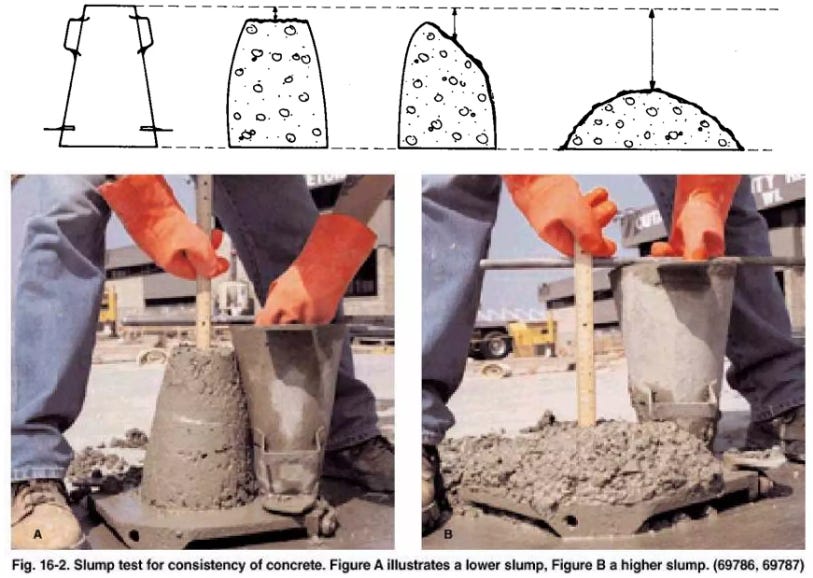

On site, being able to visually estimate the consistency of concrete (slump) is vital to understand its workability, especially when a quality-control lab is not available. The Abrams cone gives us that insight in just a few minutes.

You fill a conical mold, lift it, and measure how much the concrete subsides. That drop —the “slump”— translates into millimeters what will later mean ease (or difficulty) in compacting, pumping, or finishing the mix.

Consistency classes (EN / Spanish standards):

Dry – S1 (10–40 mm | 0–2 cm): Very stiff mixes, used in pavements or roller-compacted concrete.

Plastic – S2 (50–90 mm | 3–5 cm): For footings, walls, and elements with easy vibration.

Soft – S3 (100–150 mm | 6–9 cm): The most common range in building works: slabs, beams, floor systems.

Flowing – S4 (160 mm or more | 10–15 cm): Designed for pumping, complex formwork, or dense reinforcement.

Liquid (≥160 mm | ≥16 cm): Extremely high workability mixes, often self-compacting concretes (SCC).

⚠️ A word of caution: a high slump is not always a synonym for quality. It can mean good workability… or too much water that compromises strength. That’s why the slump test is above all a quick control tool, never a substitute for proper mix design.

💡 Key takeaway:

The Abrams cone is a simple site ritual that prevents major headaches. A kind of language between concrete and the engineer: if you know how to read it, it tells you exactly how it will behave.+

And honestly, the AI-generated images didn’t turn out that bad —as a reference, they work perfectly well.